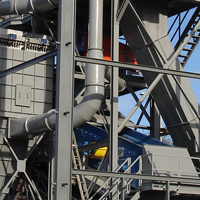

| Waste handling systems |

|

Please visit our topical picture gallery! Our waste processing systems can be suited for handling communal or biological „green” waste, pre-sorted waste, various industrial scraps or even building construction refuses. Equipment applied in waste handling systems - Conveyor belts The operating method of our general communal waste handling system: In average the aim of communal waste processing is to separate light and heavy fractions and retrieve useful materials, for example: metal, glass, etc. The communal waste can be sorted into many fractions by mechanical methods. Then separated materials can be utilised with many technological ways. After separation and utilisation the quantity of the unloaded waste can be reduced significantly. In average the mechanical preprocessing has got the following steps:

The waste is carried into the mechanical preprocessing system by garbage trucks or via transfer stations by press-containers. After weighing the waste is carried into the building of the mechanical processing system where there is a suitable sized spooler. In case of direct loading the garbage trucks unload the waste into the slat-chain conveyors’ hopper, from where the system feeds the shredder automatically and continuously, via conveyors. Provided the system can not receive the waste from the trucks, they can use the spooler. The waste can be loaded from here into the slat-chain conveyors’ hopper by wheeled loaders. The shredder grind the bigger sized pieces of the bulked waste. This way the material will be more homogenous, the size of the pieces will be smaller. After shredding further handling will be possible and more efficient. In the process of shredding mainly the big sized parts of bulked waste can be reduced such as plastics, wood boxes, pieces of furniture, accessories, etc. From the grinded material the system can retrieve the ferrous and non-ferrous metals. It is possible with magnetic belt conveyor, magnetic drum (for ferrous metals) or with eddy current separator (for non-ferrous metals). The metal pieces get into collecting bins. After metal retrieving, the waste is sorted according to the size of the pieces. For this work the screens are perfect (drum screen or vibrating screen). 70-90% of the material dropped on the screen is organic waste which can decay in biological way. This fraction is discharged directly, or across belt conveyor system into a container. After composting it can be recycled by quarries’, landfills’, spoil-banks’ landscaping. The large sized material remain on the surface of the screen and it gets into the air-blast sorter which sorts it out by density.

The light fraction can be processed in many ways. Its processing depends on the following recycling technology. The main possibilities are bailing and wrapping, collecting into opened containers or compaction containers. If the circumstances require before these steps fine shredding takes place. This description offers a brief survey of a general communal waste handling technology. Naturally, Gépsystem Kft. designs, produces and installs other systems, as well, according to costumers’ needs. |